Experimenting with Bio-Materials

- Emily Spooner

- Apr 2, 2023

- 4 min read

Updated: May 14, 2023

While researching existing Bio Materials and products I came across a range or bio-materials that can

be made from combining recycled household items with naturally derived minerals.

Inspiration-

I was also inspired by the carbon neutral bio-materials that I saw at the RIBA Long Life, Low Energy, Designed for Circular Economy exhibition. I was particularly interested in the use of food and agricultural waste solutions as my project will produce a lot of this kind of waste and it would be good to provide a solution to this issue to complete the cycle of a circular economy I am proposing. I am also going to use some moulds I made of existing materials on the site to explore how the materials could work in a casting process for custom elements of the curved building.

TEST 1- Wood Ash Concrete

First Attempt-

This is a recipe that mimics an agar bioplastic composite. The wood ash is recycled and I got mine from some home renovations my family were doing so this stops it going to landfill. The other ingredients are all derived from natural products. For example the agar is a bi-product of seaweed.

Ingredients-

- Agar 15ml

- Alginate 5ml

- Water 200ml

- Wood ash 70 grams

- Glycerol 5ml

I think the initial quantities I used to make the material were slightly off as once the material dried it turned into a jelly like product probably from adding to much agar (vegan alternative to gelatine) to the mixture. However after several days of drawing they did set pretty firmly. I did also make one batch with slightly more water that was more successful as it had less of a jelly consistency.

Outcome 1

While this sample was successful in its attempt to create a solid material due to the fact I used sawdust and not wood ash the final outcome was rough and the porous which allowed the material to grow mould over time. This problem was fixed when I added a layer of PVA glue to act as a barrier.

Outcome 2

For this sample I used wood ash like the instructions suggested and the result was much more successful in creating a dense and solid material that was able to hold its shape while also having a protective outer layer.

Development-

Using the same recipe as my first attempt I have added in used dried out coffee granules from a local café to the mixture to experiment with the colour of the finished sample.

Using a finer powder such as the coffee allowed the mixture to combine and set better so when it dried out it was a solid material rather the slightly jelly like substance in my first attempt. The use of compound with dye like quality was very successful and could definitely be applied to other mixtures.

Outcome 3

TEST 2- Eggware

This recipe mimics that of a ceramic like material that is porous and compostable once disposed of. Like ceramics it is a brittle material in its purist form. However there are natural glazes that could be added to the dried material to make it more durable.

Ingredients-

- 20g Waste Eggshells

- 5g Alginate

- 22ml Water

Outcome-

After combining the materials I created a paste that once set created a solid but spongy material that kept the indented shapes that I had made on the material sample. By using the oven I was able to speed up the drying process and by baking it in a form it kept it shape well. I don't feel that the outcome was as smooth as it could have been if I had ground the egg shells up further to a fine dust.

Development-

To create a more successful outcome I was able to use a coffee grinder to turn the remaining egg shell I had to a fine powder that combined with the other ingredients created a much smoother and well combined material that held its shape much better while still keeping the same qualities of the original sample.

TEST 3- Natural Colouring

I experimented with a variety of different natural materials that have dye properties along with different techniques for colouring the different materials.

Coffee-

Coffee works really well as a colourant that is added to the mixture of the material during the making

process. It can also substitute other materials that offer the base for the material in a powdered form, for example I experimented with substituting the wood ash from TEST 1 with coffee which actually produced a better outcome that the original mix due to the nature of the coffee granules being so fine.

Avocado-

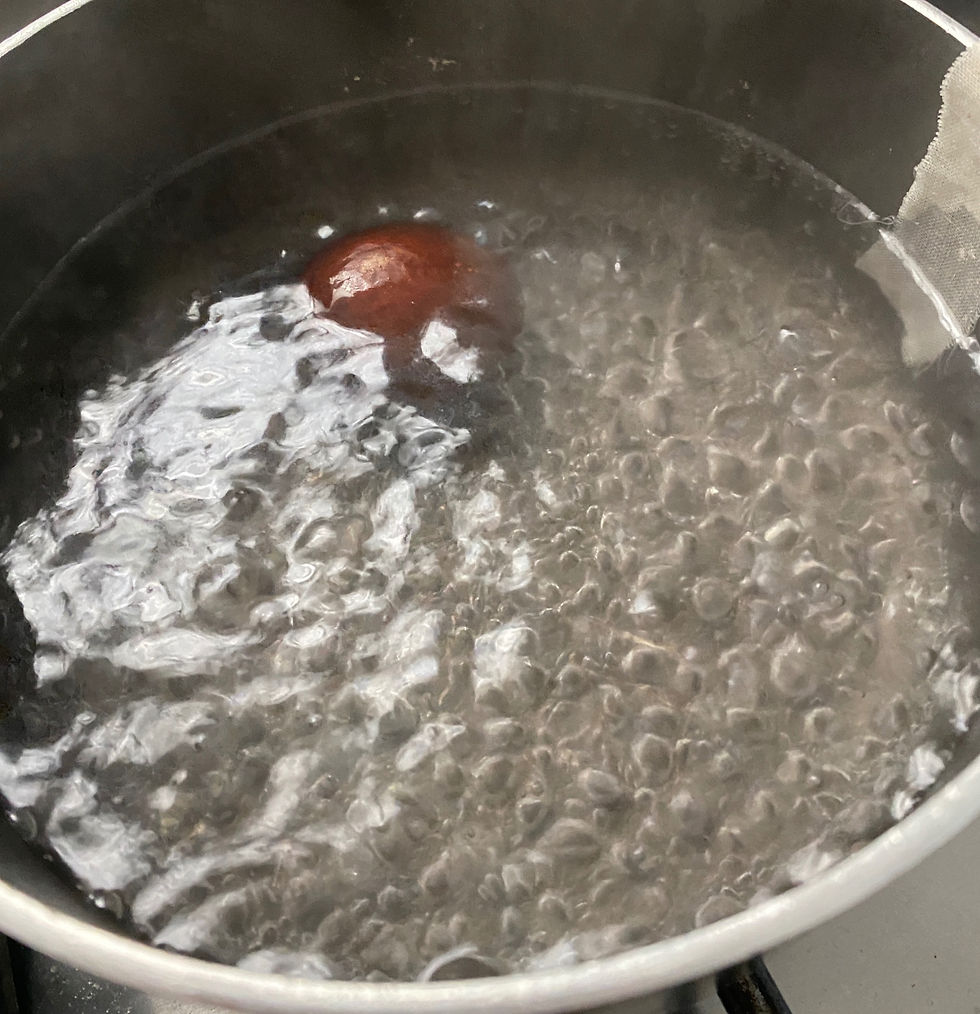

Avocado works better as a dye for a material that has already been produced as when it is boiled in water its natural pigmentation is brought out creating shades from pale pink through to dark brown.

I tried out using this method with some cotton fabric and left it in the water for varying lengths of time ranging from 5 minutes to 48 hours, the result is this range of colours.

Orange peel-

Left over orange peel can be dried out and then incorporated into material as a dry shredded power before they're set. Or alternatively they can be soaked in water like with the avocado to create a water based dye perfect for dying fabric or ceramic like materials that are porous and can absorb the colour.

References

Comments